Product

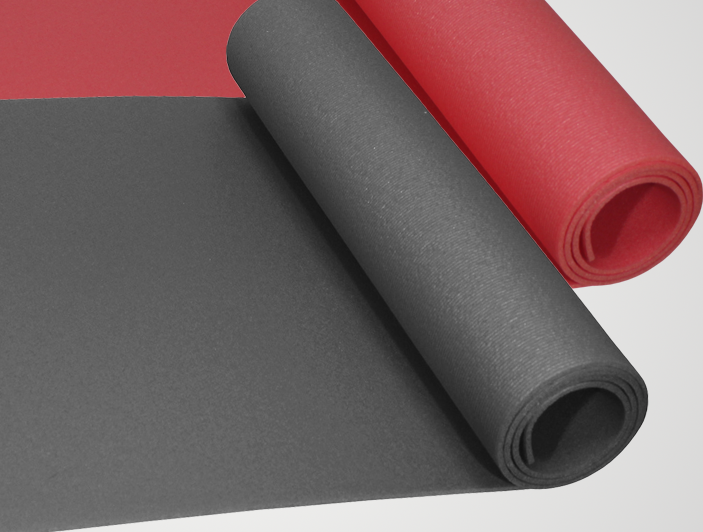

Dynafoam XPE Cross-Linked Polyethylene Foams

Dynafoam XPE Cross-Linked Polyethylene Foams are produced by extruding rigid plastic polyethylene sheets using a chemical cross-linking agent and a chemical blowing agent, followed by curing in an oven. Thanks to the production technology, the foams have a closed-cell structure and a smooth surface, providing superior mechanical and thermal properties due to the cross-linking that occurs in their structure.

DYNAFOAM XPE Products, due to their outstanding properties, are widely used in industries such as construction, automotive, medical, white goods, packaging, and many others. Chemical cross-linked polyethylene foam has a very fine and uniform cellular structure, making it ideal for projects and applications that require thick foam.

- Has a closed-cell structure, providing thermal insulation.

- Water and moisture resistant. The capillary water absorption rate is zero.

- Reduces impact noise.

- Environmentally friendly, free from HCFC and harmful/forbidden chemicals.

- Does not contain materials harmful to human health.

- Antibacterial.

- Not affected by chemicals and environmental conditions.

- Does not collapse after impact due to its flexibility.

- Can be heat-formed.

- Available in different thicknesses and sizes.

Construction Industry

- Thermal Insulation

- Sound Insulation

- Underfloor Insulation

- Under-parquet Insulation

- Wall Insulation

- Mechanical System Insulation

- Roof Insulation

HVAC Industry

In residential, industrial buildings, hotels, shopping malls, and other structures, heating, ventilation, and air conditioning (HVAC) systems are used to ensure the comfort and productivity of the people who live and work in these buildings. The choice of insulation material for HVAC systems is of great importance for both the system's and human health. DYNAFOAM XPE, with its closed-cell structure, low water absorption, dust-resistant, and vapor diffusion resistance, is widely preferred in the HVAC sector.

Automotive Industry

Thanks to its lightness and superior properties in sound, heat, moisture, and impact insulation, DYNAFOAM XPE is used in the automotive industry in many areas to reduce vehicle weight and increase driving comfort. Reducing vehicle weight to lower fuel consumption and improve performance is a priority in the automotive sector. Studies have been conducted for many years to reduce vehicle weight by increasing the use of polymer-based materials. Polymer-based materials, with their lower density and higher strength-to-weight ratio compared to metallic materials, have become one of the most important material groups for the sector due to their ease of shaping. Recently, it has been observed that vehicle weight can be further reduced by using Cross-Linked Polyethylene (XPE) foams. Furthermore, using thinner metallic materials to reduce vehicle weight can cause noise problems in vehicles. Cross-Linked Polyethylene (XPE) foams provide excellent solutions for common noise problems in vehicles. DYNAFOAM XPE, due to its closed-cell structure, water resistance, acoustic insulation, and impact damping features, meets the high standards of the automotive sector. Our company can perform lamination and sizing operations on DYNAFOAM XPE products according to customer requests.

Packaging Industry

DYNAFOAM XPE sheets are widely used in various sectors such as electronics (TVs, computers, etc.), measuring and weighing devices, medical equipment, sports equipment, and many others. These sheets are multi-purpose and, due to their flexible structure, can absorb mechanical impacts. They protect packaged products from crushing, cracking, shrinking, breaking, scratching, etc., and can be easily cut and shaped.

White Goods and Electronics

Thanks to their lightness, flexibility, superior mechanical properties, and sound, moisture, and impact insulation characteristics, DYNAFOAM XPE products are widely used in the white goods and electronics industries. Our company can perform lamination, coating, slitting, slicing, cutting, and shaping operations on DYNAFOAM XPE products according to customer requests.

Sports, Entertainment, and Mountaineering

In the sports and entertainment sectors, DYNAFOAM XPE offers numerous product alternatives due to its lightness, flexibility, antibacterial properties, and absence of harmful substances such as HCFC. Our company can perform lamination, coating, slitting, slicing, cutting, and shaping operations on DYNAFOAM XPE products according to customer requests.

Bags and Footwear

DYNAFOAM XPE products are widely used in the footwear and bag industry due to their lightness, antibacterial properties, water resistance, odorlessness, resistance to impact, and lack of harmful substances such as HCFC. Our company can perform lamination, coating, slitting, slicing, cutting, and shaping operations on DYNAFOAM XPE products according to customer requests.

Healthcare and Medical

Due to its closed-cell, flexible, and smooth pore structure, antibacterial properties, and the absence of harmful substances such as HCFC, DYNAFOAM XPE can be used in medical and healthcare industry products. DYNAFOAM XPE medical packaging, medical tapes, orthopedic and prosthetic fillings, wheelchair pads, and medical inner caps are some of the applications.